Products

Home > Products > Mechanical Parts > Composite Parts > Metal-Resin Composite

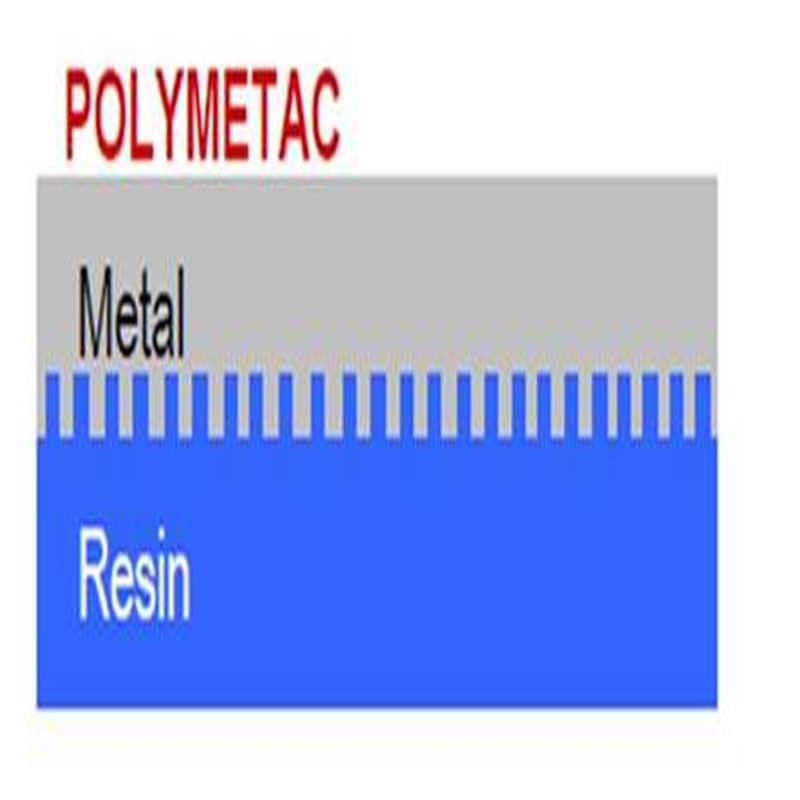

Metal-Resin Composite

- Features

- Improve anti-corrosive property of metal and weathering resisitance of resin

- Keep mechanical strength of metal

- High peel strength between metal and resin

- Light and downsized

- Improve product artistry

- Save engineering and assembly cost

- Application

- Metal-resin integration technology

- Add functions of resin to metal

- Add functions of meatl to resin

- Increase the functions of metal

- Improve the efficiency of assemly

- Specification

- Please contact us directly for further information.